Many obstacles will arise when trying to keep a building 30-50°F warmer or cooler than the outside temperature. The aim of the HVAC system is to keep the buildings’ inhabitants comfortable and healthy while considering system costs. When designing and installing multi-floor supply and exhaust systems, balancing can become an issue. Fan pressures and thermal stack affects can cause differences in how much supply/exhaust air each floor experiences. When spaces experience the incorrect amount of supply/exhaust air it can affect the humidity, air quality, and cost to condition the space. Constant Volume Regulators (CVR) are a simple solution to combat these problems. These simple cylindrical devices automatically control the passage of air without the use any electric controls or sensors, making them a cost-effective solution.

Challenges

Fan Induced Pressure

Most multi-floor buildings have individual HVAC systems that serve more than one floor. This can be exhaust fans or dedicated outside air systems for supply ventilation air to the spaces. These systems include a fan that is connected to a duct that runs through a chase through the building. Each floor will have a branch duct that is connected to the common duct. Without proper balancing, the floors closer to the fans will supply/receive a disproportional amount of the air when compared to the floors further away from the fan. The traditional approach for eliminating this issue is to have a series of balancing dampers at each branch and outlet/inlet that are individually balanced to achieve equal supply/exhaust air at each floor.

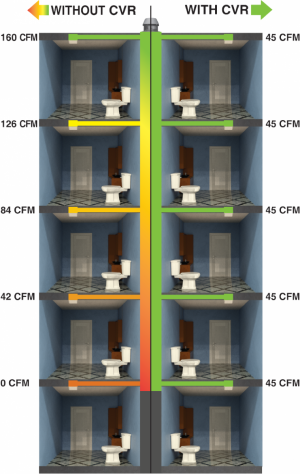

As shown in the exhaust example to the right, the floors closest to the fan will exhaust more air (cubic feet per minute) than the floors furthest from the fan. Since there is nothing to control the passage of air in the duct system for the closer floors, the air will follow the path of least resistance. This will lead to the closer floors delivering all the air it can, which is more than intended, leaving less air exhausted on the lower floors. This would typically apply for restroom and kitchen exhaust systems.

Adding a constant volume regulator at each inlet/outlet will alleviate this issue. The regulator dynamically responds to the duct environment and maintains its air flow set point. This is shown in the right-hand side of the image above.

Stack Effect

Thermal stack effect is based on the principle of hot air rising and cold air sinking. This movement of air creates a pressure difference on a building, causing air to enter or exit at the top or bottom of the building.

In warmer climates, while in cooling, the cold air, being denser, sinks, creating a pressure difference with the bottom of the building being the high-pressure portion. This causes hot air to be sucked in through the top of the building and expelled at the bottom of the building.

In colder climates, while in heating, the warm air, being less dense, rises, creating a pressure difference with the top of the building being the high-pressure portion. This causes cold air to be sucked in at the bottom of the building and hot air expelled at the top.

This causes an unwanted circulation of air coming in and out the building, causing over-ventilation and under-ventilation at different floors throughout the building. Over-ventilation leads to energy waste & humidity issues and under-ventilation leads to improper air quality.

When trying to maintain consistent supply/exhaust from multi-floor HVAC equipment, the thermal stack effects caused by changes in outdoor temperatures represent a dynamic challenge. When using traditional static balance dampers, the performance of the system will be based on the thermal environment during the original balancing. A constant volume regulator is designed to automatically respond to changes in pressure to maintain a constant air flow. This will significantly reduce the issues caused by thermal stack effects on the building HVAC systems.

What is a CVR

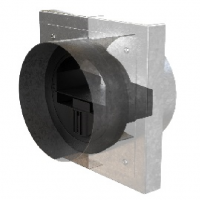

A Constant Volume Regulator (CVR) is a device used in HVAC to control the velocity of the air. It does not need controls or sensors and relies solely on a spring to accurately control the passage of air. The CVR is made of four main components: the main body, a seal, a lockable and adjustable plate, and a self-adjusting flap. The main body is a cylinder of hard and durable plastic that houses the regulating blade and contains the airflow cfm values used to set the CVR. The seal is used to ensure an air-tight seal between the CVR and the ductwork. The lockable and adjustable plate is screwed onto the main body and is positioned to its desired flowrate. The smaller the area for air to pass (equivalent to the higher the plate is positioned), the lower the desired cfm value. The self-adjusting flap is attached to the lockable and adjustable plate. It has a spring that holds the flap down. This flap is designed to capture air underneath it that will push the flap higher up as the flow speed increases. The higher the velocity of the air, the higher the blade moves, creating a smaller opening, which reduces the amount of air that can pass. As the velocity of air fluctuates, the spring continuously adjusts the flap to maintain the airflow set point.

How the CVR Helps

The CVR is applicable in many applications that require the air flow to be a consistent specific value in duct systems that have variable air flow. The CVR is capable of handling both intake and exhaust applications with no extra attachments or changes. Without the need for controllers or sensors, easy installation, and minimal maintenance, make the CVR is a cost-effective solution when compared other methods. The CVR can be installed after construction to alleviate the issues described above..

Nailor CVR Options

CVR

CVR-SP – Standard Pressures

CVR-SP – Standard Pressures

-

CVR-LP – Low Pressures

-

CVR-HP- High Pressure

The CVR’s may contain shims used when a lower airflow is needed in larger ducts. This product is easily installed by sliding the CVR into the designated duct size. The seal provides an airtight seal between the CVR and the duct.

CVR-T

The CVR-T model comes equipped with a factory mounted duct transition. This allows the CVR to be installed in square or rectangular shaped ducts.

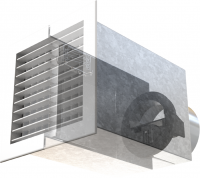

CVR-FD

The CVR-FD is an all in one, easy to install CVR and a UL 555 Listed 1 hour static or dynamic curtain fire damper in a flanged box with a grille. This model features reduced installation times, and does not use rear retaining angles, making it a great complete option.

The CVR-FD is an all in one, easy to install CVR and a UL 555 Listed 1 hour static or dynamic curtain fire damper in a flanged box with a grille. This model features reduced installation times, and does not use rear retaining angles, making it a great complete option.

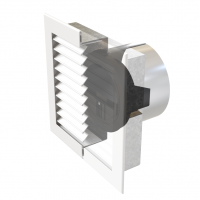

CVR-GM

The CVR-GM is a factory assembled CVR in a flanged plenum box with a grille. Used in applications where fire dampers are not required, this model comes preassembled for quick and easy installation. Constant Volume Regulators are a simple and elegant solution for balancing multi-floor supply/exhaust systems.